Insights on Ghee & Butter and its Production Process

Overview of Butter

Butter is a dairy product containing up to 80% butterfat which is solid when chilled and at room temperature. It is made by churning fresh or fermented cream or milk to separate the butterfat from the buttermilk. Butter consists of butterfat, milk proteins and water.

According to PFA rules (1976), table or creamery butter is the

product obtained from cow or buffalo milk or a combination thereof, or from

cream or curd obtained from cow or buffalo milk, or without the addition of

common salt and annatto or carotene as colouring matter.

The specifications of butter as defined by PFA are as follows:

ü It should be free from other animal fats, wax

and mineral oils, vegetable oils, and fats.

ü It should not contain any preservatives except

common salt.

ü It should not contain any colouring matter

except annatto or carotene.

ü It must contain not less than 1.5 per cent by

weight of curd, and not more than 3 per cent by weight of common salt.

ü Total diacetyl (if added) must not exceed 4

ppm.

ü Sodium carbonate/bicarbonate, calcium

hydroxide (if added) should not exceed 0.2 per cent by weight of butter.

Butter is essentially the fat of milk. It is

essentially a water-in-oil emulsion and is usually made from sweet cream and is

salted. Salt less (sweet) butter is also available in the market. Butter can

also be made from acidulated or bacteriologically soured cream. Commercial

butter can be produced from both sweets as well as cultured cream.

Extraordinarily little cultured butter is produced in India and the U.S.A.,

although in Europe and Canada, cultured butter is an important product.

However, most creameries prefer to produce butter from sweet cream as it

results in sweet buttermilk with better economic value than sour buttermilk

that results when sour/cultured cream is churned.

Composition of Butter -

The composition of the

butter is approximately the following: fat 81.5% -82.4%, water 16.5-17.5%,

while the dry matter that does not contain fat is 0.6-1.6%. The dry matter

contains a small percentage of protein, milk sugar and salt that has been added

during the processing of fat and its conversion into butter. The color of the

butter depends on the type of milk we use. Cow’s milk gives a slightly yellow

butter, which is due to the fat content of the milk in β-carotene. Unlike cow

dung, goat butter is white and this is because the goat converts the β-carotene

it receives in its food to vitamin A, which is colorless.

Butter is basically

produced in two types: in hard, whose composition we mentioned above and which

is the well-known butter, which is sold in stores and in liquid butter, which

contains up to 98% fat. The raw material for the production of butter is cow’s

milk, which, depending on the breed to which the cow belongs, contains from

about 3-6%. Butter can also be made from buffalo milk, as well as from goat’s

milk which is considered the most beautiful or sheep’s.

Raw or fresh or even

hard butter may taste sour or sweet, depending on the method of processing

followed. Butter has great nutritional value, because it is one of the best

sources of calories. It is very easy to digest and contains a large amount of

vitamin A, as well as vitamin D.

Butter

Manufacturing Process –

Reception

of the milk: As the milk arrives, a sample is sent

to the lab for initial analysis (fat, SNF, etc.); if it fits the standards, it

is sent to the storing silos.

Separation:

Milk is transferred to the separator, where it is separated into cream and skim

milk. The skim milk from the separator is pasteurized and cooled before being pumped

to storage. It is usually concentrated and dried.

Pasteurization:

It is usually done at 82-88°C or more. (The high temperature is needed to

destroy enzymes and micro-organisms that would impair the butter’s keeping

quality).

Ripening:

Sometimes, cultures are added to ferment milk sugars to lactic acid for

acquiring desirable flavour and aroma characteristics to get some cultured

butter. This is more common in European butter. Thus, ripening is the

fermentation of cream with the help of a desirable starter culture, which helps

develop flavour. The cream is ripened in 2 stages: 1st stage at 21°C to pH 5.5

and then 2nd stage at 13°C to pH 4.6. This step can be eliminated if sweet-cream

butter is desired. So, once the cream is pasteurized, it is transferred to the

cream storage tank for ripening.

Ageing

and crystallizing: The cream is now transferred to the

ageing tank and subjected to a controlled cooling program that gives the fat

the required crystalline structure. The process is done for around 8 hrs at

14°C.

Churning:

The aged cream is now sent to the churner. In the churning process, the cream

is violently agitated for 30 min at 6-14° C to break down the fat globules,

causing the fat to coagulate and form butter grains and buttermilk.

Draining

& washing: It used to be common practice to wash

the butter after churning to remove any residual buttermilk and milk.

Salting:

After washing the butter granules, they are transferred to the blending tank

and mixed with Salt.

Packing

& storage: The butter is finally patted into

shape and then wrapped in waxed paper, and then stored in a cool place. As it

cools, the butterfat crystallizes, and the butter becomes firm.

Note-

Neutralization of cream has to be done in the butter making process. Churning

of High acid cream may cause high-fat loss, which can be prevented by

neutralization. Thus, the objectives of neutralization are to reduce the

acidity in cream to a point (0.14 -0.16%) which permits pasteurization without

risk of curdling, to produce butter that keeps well in cold storage.

Difference

between Butter, Table Butter, and White butter -

Conclusion -

Traditionally, butter is a product derived from cream, inverted to a water-in-oil emulsion (W/O) with a minimum of 80% fat. The butter’s continuous fat phase is a complex matrix of liquid butter oil and fat crystals, forming a network that entraps the water droplets and, to a limited extent, small air bubbles. Initially, the milk is concentrated to cream followed by a pasteurization process. Subsequently, the cream follows a temperature treatment where crystallization takes place. The churning process involves phase inversion of the crystallized cream to butter granules and buttermilk. The butter granules are plasticized by the kneading and mixing process to form the butter. To improve the butter quality, the system is equipped with a vacuum suction/De aerator in which the incorporated air is removed. Removal of air from the butter will improve the butter’s texture and increase the shelf life due to less oxidation and the risk of free moisture.

Overview of Ghee

Ghee is a type of clarified butter that contains fewer dairy proteins than regular butter. Ghee is a form of highly-clarified butter that is traditionally used in Asian cooking. Like butter, ghee is typically made from cow’s milk. Ghee is made by melting regular butter. The butter separates into liquid fats and milk solids. Once separated, the milk solids are removed, which means that ghee has less lactose than butter.

Traditionally, ghee has been used as cooking oil, an

ingredient in dishes, and in Ayurveda therapies. Ghee is still used in

Ayurvedic massage and as a base for herbal ointments to treat burns and rashes.

Ghee is heated for longer than other types of clarified butter,

which contributes to a stronger and nuttier flavor, as well as a darker hue. Ghee

has a higher burning point than standard clarified butter, which means it is

ideal for frying or sautéing foods. Butter can smoke and burn at 350°F (177°C),

but ghee can withstand heat up to 485°F (252°C).

Ghee also produces less of the toxin acrylamide when heated

compared to other oils. Acrylamide is a chemical compound that develops when

starchy foods are prepared at high temperatures. This chemical has been

known to increase the cancer risk in lab animals, but it’s unclear whether

it also increases the cancer risk in humans.

Because ghee separates milk from fat, this butter substitute is

lactose-free, making it better than butter if you have allergies or

sensitivities to dairy products.

Ghee has a slightly higher

concentration of fat than butter and more calories. One tablespoon of ghee has

about 120

calories, whereas one tablespoon of butter has

about 102 calories.

India is the world’s largest producer

and consumer of milk and dairy products. Ghee currently controls the second

largest market share in terms of revenue in the Indian market. With the growth

of the organized sector of the dairy industry and establishment of modern dairy

plants, the emphasis has shifted to conducting investigations on newer and

larger-scale methods of ghee manufacture which could profitably be adopted for

routine ghee production by these dairies instead of the desi method used in the

dairy.

There are five methods of Ghee

Processing:

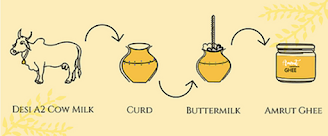

Desi Method:

It is an age-old process adopted mainly in rural areas/villages and at urban household levels because of simplicity in equipment and technique. This traditional method of making ghee contributes about 80% of the total ghee produced in the country. This method usually involves two routes-

- Lactic acid fermentation of raw or heated milk is followed by the churning of curd into Makkhan (butter).

- Separation of malai (clotted cream) from the boiled milk and its churning into butter, which is further heated to make ghee.

Now-a-days electrically operated butter churns are available.

Makkhan is stored at room

temperature for days together and when sufficient quantity accumulated, it is

converted into ghee. For this purpose, makkhan is heated in a earthen pot

(now-a-days metal, particularly steel or aluminum containers are also used) on slow

fire. The scum gathered on the top of melted butter is continuously removed

with perforated ladle. The heating is discontinued on complete removal of scum

and froth and getting clear fat (ghee). There are several limitations in this

process which are mentioned here:

- The quality of ghee is highly inconsistent in terms of chemical and sensory quality.

- Method is incompatible to large-scale production.

- Recovery of fat is low.

- Acidity is high and hence keeping quality is low.

- Manufacture and storage of ghee is done in undesirable containers.

- Ghee residue being acidic in nature cannot be used.

The

indigenous method is not adopted by organized dairies. Most of the ghee

produced by this method is either consumed for household purpose or serves as a

base material for the blending operations at ghee grading and packing centers

functioning under Agricultural Marketing and Grading (AGMARK) scheme in India.

Direct Cream Method:

The direct cream method is a commercial ghee

manufacturing process. Here a kettle is used to boil the milk cream. These

kettles are mostly made of steel, and they come with a steam-heated jacket and

fixed with an agitator, a steam regulator valve, pressure, and temperature

gauging devices and a portable, hollow, stainless steel tube with central

boring for draining out the contents.

Heating gets stopped when brownish froth is seen on the surface, and the

color of the ghee residue becomes golden yellow or light brown. The small

dairies use a technologically improved method for ghee making which involves

the separation of cream from milk by centrifugation.

Note: One of the important drawbacks of the direct-cream-ghee process is a lower percentage recovery of ghee as compared with the creamery-butter process. This is because ‘normal’ cream (40-50 per cent fat) contains much more solids-not-fat (about 4.5 to 5.5 per cent) than desi or white butter (1 to 1.5 per cent). This higher solids-not-fat content in cream contributes to a larger ghee-residue, which in turn causes a greater fat loss in the same.

Earlier workers have shown that the non-fatty milk solids of cream, can be reduced by what has been termed the ‘cream washing’ process. This process consists of diluting the cream with lukewarm water (40°C) equal to the volume of the original milk. After thoroughly mixing it by gentle stirring, the diluted cream is then separated without altering the conditions of normal cream separation. This washed cream contains 1-2 per cent solids-not-fat. When converted into ghee in the usual manner, it gives a higher yield.

However, the ghee has a flat flavour,

although the product also has a longer shelf-life. Artificial ripening of the

washed cream with lactic starter to an acidity level of 0.20 per cent lactic,

or acidification of the cream with citric acid to the same level prior to

clarification as above, improves the flavour of the finished ghee.

An alternative to cream washing is the

use of plastic cream, containing 65-85 per cent fat and a very low

solids-not-fat content. This requires a special cream separator called a

plastic cream separator. It is understood that a few ghee manufacturers in India

have been using the direct-cream heating method and plastic cream for their

routine production.

Creamery-Butter Method:

In this method, unsalted creamery butter or white butter or cooking butter

is used as a raw material for ghee making. First, the butter mass is melted at

60° C. The molten butter is pumped into the ghee boiler. The steam pressure is

increased slowly to raise the temperature of

butter to 90° C. This temperature remains constant as long as the moisture is

being driven off. The scum, which collects on the top surface of the product is

removed from time to time. The temperature gradually rises, and the heating at

the last stage is carefully controlled. The disappearance of effervescence, the

appearance of finer air bubbles on the surface of fat and browning of the curd

particles shows the end-point. At this stage, the typical ghee aroma is also

produced. The final temperature of clarification is adjusted less than 115° C.

The ghee is then pumped, via oil filter or clarifier, into another tank, cooled

by re-circulating water at 60° C. The ghee is then packed in suitable

containers.

Pre-Stratification Method:

Butter is produced from aged cream of 38 to 40% fat using continuous butter making machine or batch churn. Butter is then transferred to butter vat, and melted at 80°C. This molten butter is kept undisturbed in a ghee kettle or boiler at a temperature of 80-85°C for 30 min. Here, in ghee kettle, stratification of mass takes places, and the product stratifies into three distinct layers. Denatured protein particles (curd particles) and impurities are collected on the top layer and floats. The middle layer consists of clear fat and bottom layer consists of buttermilk serum carrying 80% of moisture and 70% of solids-not-fat contained in butter.

Continuous Method:

The batch methods for making ghee discussed earlier are highly suitable for small and medium scale production of ghee. With the increase in demand and scope for export of ghee, some very large organized dairies prefer to adopt a continuous ghee making methods. Some of the problems associated with the current batch methods of ghee making are:

§ Unsuitable for

large-scale production.

§ High-energy

consumption.

§ Excessive strain

and fatigue on the operators.

§ Product exposed

to the environment.

§ Cleaning of

equipment is done manually.

All the limitations of the conventional batch methods given above are obviated by continuous ghee making plants. Some of the benefits of continuous method of ghee preparation are as follows:

·

Better

control on quality of the product

· Only

small hold-up of raw material in the plant at any time and hence no chance for

whole batch getting spoiled

· Contamination

by handlers can be eliminated

· CIP

can be possible

· No

foaming of the product during production

· Suitability for large-scale handling

· Utilization of machines for a large number of production-

processes feasible

· Uniform demand on services

- No stirring, no scraping and no laborious effort on the part of

the ghee operators required.

· High fat recovery;

Objectives:

(i) To manufacture ghee on an industrial

scale as a continuous process, to ensure uniform quality, and greater economy.

(ii) To reduce human labour, drudgery and fatigue by introducing as much automation as feasible or desirable under Indian conditions.

Continuous systems work on the basis of two

principles, viz. (a) moisture evaporation from cream/butter using thin film

scraped surface heat exchanger (TSSHE) and (b) de-emulsification of cream using

high speed clarifixator and oil concentrator followed by moisture evaporation.

TSSHE

for continuous ghee making- The white or cooking butter from continuous butter

melter is pumped in balance tank where it is kept agitated by means of agitator

to maintain the homogeneity of molten butter. Then the butter is pumped to the

TSSHE. The flow rate of molten butter is indicated by a rotameter and

controlled with a value provided on the inlet line. The centrifugal action of

the rotor blade make the molten butter spread uniformly in form of a film on

the heating surface of the SSHE. Steam is admitted at regulated rate into the

jacket of SSHE. The rate of evaporation of water from the butter film is very

fast due to turbulence caused by the action of rotating blade. The speed of

rotor blade is controlled by a motor drive. The vapour is removed through the

outlet provided at the top of the SSHE and can be used for heating the butter

in balance tank, thus economizing the steam consumption. The temperatures of

molten butter and ghee are indicated by thermometers and adjusted by controlled

steam supply with valves. Ghee is collected continuously in the ghee tank. The

residue is separated from ghee by the oil clarifier. Residue free ghee is

finally transferred to packaging line/tank.

Cream

de-emulsification method: This method of continuous ghee making is based on

the principle of de-emulsification of fat in cream from oil-in-water phase to

water-in-oil phase. In this process milk is separated into cream of 40% fat

using a centrifugal cream separator. This cream is converted into plastic cream

of 80% fat in a clarifixator and then further concentrated in a concentrator,

which work under centrifugal force. The de-emulsification of fat is done

mechanically in the clarifixator and concentrator. Scraped surface heat

exchanger is used to generate flavour and remove most of the moisture from fat

concentrate. The traces of moisture left in ghee are removed in a vapour

separator and the ghee residue removed by an oil clarifier.

Conclusion -

Ghee is an essential part of Indian diet, religious, ceremonial function, and therapeutic purposes. Ghee is broadly prepared by two methods: traditional method and industrial method viz. creamery-butter method, direct cream method, pre-stratification method, and continuous method. On the word of market dynamics, more than 90% of the ghee is produced by traditional method by unorganized sectors in India by making butter (makkhan) and then converting it into ghee.

Comments

Post a Comment