What are Stabilizers and Emulsifiers?

Introduction

Emulsifiers are substances which make it possible to form or maintain a homogenous mixture of two or more immiscible phases such as oil and water in a foodstuff.

Emulsifiers are Food and Drug Administration–approved food additives that help products containing immiscible food ingredients, like oil and water, to combine. You can find emulsifiers in plenty of prepackaged and processed foods, including mayonnaise, margarine, meats, ice cream, salad dressings, chocolate, peanut butter and other nut butters, shelf-stable frostings, cookies, crackers, creamy sauces, breads, baked products and ice cream.

Emulsifiers can be man-made or naturally occurring. Many emulsifiers used today are of a naturally derived variety called hydrocolloids. Hydrocolloids serve as thickening agents and support the structure, texture, flavor, and shelf life of various food products, and they are often referred to simply as gums because of the food texture and consistency they create. Hydrocolloids include emulsifiers made from plants, animals and aquatic sources. Plant-based hydrocolloids include locust bean gum, carrageenan, pectin, and starch, while animal-sourced varieties including chitosan made from crustacean shells. Hydrocolloids, like xanthan gum, can also come from microbial sources, and even food products themselves—mustard, oil, salt, egg yolk and vinegar—can serve as emulsifiers.

Emulsifiers have one water-loving (hydrophilic) and one oil-loving (hydrophobic) end. When they are added to an unmixable liquid, the emulsifier molecules position themselves along the so-called interfacial layer where the oil separates from the water. Here, the emulsifier is positioned in such a way that their hydrophilic end faces towards the water phase and their hydrophobic end faces the oil phase, making it possible for the water and oil to become finely dispersed in each other. In the end, the emulsifier creates a stable, homogenous, and smooth emulsion.

Stabilisers are substances which make it possible to maintain the physico-chemical state of a foodstuff; stabilisers include substances which enable the maintenance of a homogenous dispersion of two or more immiscible substances in a foodstuff and include also substances which stabilise, retain or intensify an existing colour of a foodstuff.

The integrity of a food product is essential in delivering an outstanding experience to the customer. Over time, certain foods tend to lose their original structure: Oils will separate, ingredients will degrade, and some foods may actually change in shape.

To ensure food products maintain the highest possible quality in transit to the customer, manufacturers rely on food stabilizers. These substances extend the shelf life of many foods, and can be found in both cupboards and refrigerators across the nation.

A food stabilizer is an agent added to food products to help maintain or enhance their original texture, physical and chemical characteristics. They serve both the practical purpose of preservation while also making products far more appetizing to consumers.

Let's take an example of ice cream and explain the role of both stabilizers and emulsifiers.

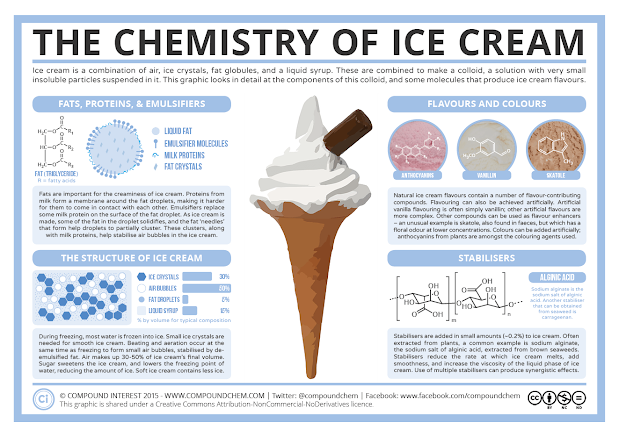

Ice cream is a complex food colloid that consists of air bubbles, fat globules, ice crystals and an unfrozen serum phase. Ice crystals and air bubbles are generally in the range of 20–50 μm. The air bubbles are usually to some extent coated with fat globules and the fat globules are coated with a protein/emulsifier layer. The serum phase consists of the sugars and high molecular weight polysaccharides in a freeze-concentrated solution. Various steps in the manufacturing process, including pasteurization, homogenization, ageing, freezing, and hardening, contribute to the development of this structure. Proteins and emulsifiers compete for inter facial space during the homogenization of the fat and the creation of the mix emulsion. Following homogenization, the emulsion is further affected by changes occurring during the ageing step, viz, crystallization of the fat and rearrangement of the fat globule membrane to the lowest free energy state. This emulsion then undergoes both whipping and ice crystal formation during the dynamic freezing process, which contributes to the development of the four main structural components of the frozen product: discontinuous foam, a network of partially coalesced fat surrounding the air bubbles, ice crystals, and a continuous, freeze-concentrated, unfrozen aqueous solution

Stabilizers and emulsifiers have been conventionally used in ice cream as additives. Recently, there has been a tendency towards ‘all natural’ or ‘natural’ products which have given rise to the so called premium ice cream which is supposed to contain no additives. Yet because of the quality enhancing ability of stabilizers and emulsifiers, they remain as important ingredients for most ice creams and frozen desserts.

Stabilizers are substances which make it possible to maintain the physico-chemical state of a foodstuff; stabilizers include substances which enable the maintenance of a homogenous dispersion of two or more immiscible substances in a foodstuff and include also substances which stabilize, retain or intensify an existing colour of a foodstuff. Emulsifiers are surface active agents which improve the sensory quality of ice cream by aiding the whipping process, improve air cell distribution and enhance the products heat shock resistance. Despite their name, emulsifiers are actually used in ice cream to de-emulsify some of the fat.

Stabilizers

Stabilizers are a group of water-soluble or water-dispersible biopolymers used in small amounts (typically 0.2%) in ice cream, sorbets, water ices and other foods. Most stabilizers are polysaccharides of plant origin, e.g. alginates and carrageenans (from seaweeds), locust bean gum and guar gum(from tree seeds), pectin (from fruit) and sodium carboxymethyl cellulose (from cotton). Xanthan, a bacterial polysaccharide, and gelatin, a polypeptide of animal origin, are also sometimes used. These biopolymers are polydisperse and poly-molecular, because their structures vary with the source and the environmental conditions. Nutritionally, stabilizers are a source of soluble fibre. Although they come from natural sources, under European law they are considered food additives and therefore they have associated ‘E numbers’.Stabilizers are straight or branched polymers containing hydroxyl groups that can form hydrogen bonds to water molecules. Typically they contain numerous monomer units and have molecular weights of 105-106. Because they are large, stabilizers do not dissolve in water as readily as smaller molecules: some require high temperatures or shear for complete hydration. When dissolved, they produce high viscosity solutions at low concentrations. Some stabilizers in solution can form gels when heated and/or cooled or on the addition of cations.

Role of Stabilizers in Ice Cream

In ice cream, stabilizers, usually used in combination of 2-3 types are primarily used for the following purposes:

- To increase the viscosity of the mix.

- To stabilize the mix i.e. to prevent wheying off

- To help in suspension of flavouring particles.

- To produce a stable foam with desired stiffness at the time of packaging

- To reduce or slow down the growth of lactose crystals during storage mainly during temperature fluctuations.

- To reduce moisture migration from the product to the package or the air.

- To help prevent shrinkage of the product volume during storage.

- To provide uniformity to the product and resistance to melting.

- To produce smoothness in texture during consumption.

- Reduce the rate of meltdown (i.e. the rate at which ice cream melts).

- Prevent shrinkage and slow down moisture migration out of ice.

- Mask the detection of ice crystals in the mouth during eating.

- Allow easier pumping and more accurate filling during processing.

- Facilitate the controlled in corporation of air in the freezer.

Classification of stabilizers

Stabilizers which are used in ice cream and frozen desserts mainly fall into the following categories

1. Proteins- Gelatin

2. Plantexudates – Arabic, ghatti, karaya and tragacanth gums

3. Seed gums – Locust ( carob) bean, guar, psyllium, starch and modified starches

4. Microbialgums – Xanthan

5. Seaweed extracts – agar, alginates, carageenan

6. Pectins– low and high methoxyl

7. Cellulose– sodium carboxymethyl cellulose, microcrystalline cellulose, methyl and methylethyl cellulose, hydroxypropyl and hydroxypropylmethyl cellulose.

Emulsifiers have been used in ice cream mix manufacture for many years. They are usually integrated with stabilizers in proprietary blends but their function and action differ remarkably from those of stabilizers. They can be classified as :

- Hydrophobic: Examples include sorbitan esters,mono- and diglycerides of fatty acids, polyglycerol polyricinoleate, highly substituted sugars, polyglycerol esters, and propylene glycol esters.

- Hydrophilic: Examples include ethoxylatedsorbitan esters, monoglyceride derivatives such as lactates, tartarates,citrates, low-substituted polyglycerol esters, and monosubstituted sugaresters.

Role of emulsifiers in ice cream

Emulsifiers are used to:

- Promote nucleation of fat during aging thus reducing aging time

- Improve the whipping ability of the mix due to their function at the air interface resulting in reduced air cell sizes and homogenous distribution of air in the ice cream.

- Produce a dry and stiff ice cream as they enhance fat destabilization, facilitating molding, fancy extrusion and sandwich manufacture.

- Increase resistance to shrinkage and rapid melt down due to a combination of the above two factors.

- Increase resistance to the development of coarse/icy texture, due to the effect of fat agglomerates, more numerous air bubbles, and thinner lamellae between adjacent air bubbles on the size and growth of ice crystals.

- Provide smooth texture in the finished product, due to fat structuring and interaction of fat agglomerates within the mouth during consumption.

- Mono- and diglycerides of fatty acids: as you might remember, fats and oils are triglycerides: a glycerol molecule with three attached fatty acid chains. Mono- and diglycerides also have this glycerol structure but they have only one (mono) or two (di) fatty acid chains attached to them. The glycerol section prefers to sit in the water, whereas the fatty acid chains prefer fat, thus keeping the two mixed.

- Lecithin: it sits in egg yolk but can also be derived from soy. In most cases this soy lecithin is what’s used in ice cream. Lecithin is a small molecule with a head and a tail. The head likes to sit in water whereas the tail likes to sit in oil. This way the lecithin will sit on the interface between the two and help stabilize them. Lecithin is an amphiphilic emulsifier, as is shown below.

Comments

Post a Comment